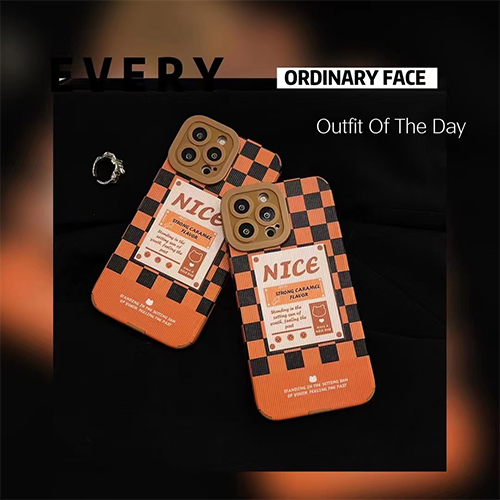

The production of mobile phone cases, at present, has been a high voice. After all, mobile phones are our daily life with things. Search the production process, it is really multifarious, variety, a hundred flowers bloom. Common are silicone soft case, plastic hard case (generally surface printing), leather case, and hybrid with metal finger buckle mobile phone case, an article will never finish. Speaking of soft silicone, I found monochrome, multi-color, batch and other different assembly lines. Without saying much, today's seeing is believing is only talking about silicone phone case production.

Monochrome batch

Some like plasticine soft material, is the production of silicone mobile phone case silicone raw materials. After careful mixing test, the operator is familiar with the way, no less than put in the batch of 6 raw materials.

The machine used is the hot pressing machine, also known as the vulcanizing machine. Set the required temperature, pressure, time and other parameters, and then the molding machine to pressure vulcanization of silica gel, time to the silica gel raw material will soften and solidify, become the shape of the mobile phone case ~ workers hand from the silica gel shell and plug down the bottom of the mold, is used to act as a mobile phone case core.

A batch of 6 silica gel mobile phone cases are conveniently removed from the upper mold base by air spray, and then cut.

This should be the simplest phone case model in the batch. The mold is a simple upper and lower mold, plus a movable middle core to act as the volume of the phone.

Simple monochrome

Silicone material is still put in, but the core with a long handle is pressed on the lower die, and then the upper die.

After hot press vulcanization, we pry open the upper die. We can see that there is an obvious vacancy for the camera on the core, and the long handle is a good position for the charging port, but the lens is too fast to see clearly.

On the other hand, a monochrome silicone phone case with multiple holes is removed from the core.

After that, you have to send the phone case to trim and add sulfur, and if you need it, you can make a pattern on the outside of the monochrome silicone case.

Easy and multi-colored

Firstly, a relatively simple splicing color mobile phone case is introduced. Silica gel materials of different colors are put on different molds. The one on the left is the upper mold, which already has the pink and white trapezoidal material. The core on the right and the lower die are the main material put directly.

Take the mold apart and see if you can clean it with air blowing.

Looking at the results on display, this is a simple multi-color scheme.

Complex multi-color style

First, the base color is directly applied to the top layer of the mold, using liquid paint. Put it in the oven to set the paint. Then the gray main material is put silica gel raw material, vulcanization pressure. Split the mold and spread out several parts. Did you find the freshly baked Mickey, which was mirrored? Complex multi-color silicone phone case.

And many cute mobile phone cases with ears are similar. First, fill the shape color into the mold and send it to the oven for fixing. Then, put green raw materials into the main body and ear part of the mobile phone case respectively.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  עִברִית

עִברִית  Galego

Galego  Беларус

Беларус  Hrvatski

Hrvatski  Shqiptar

Shqiptar  Bosanski

Bosanski  Frysk

Frysk  IsiXhosa

IsiXhosa  Somali

Somali  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  հայերեն

հայերեն  Lëtzebuergesch

Lëtzebuergesch  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা

বাংলা  Dansk

Dansk  Pilipino

Pilipino  Türk

Türk  Gaeilge

Gaeilge  عربى

عربى  Indonesia

Indonesia  norsk

norsk  Ελληνικά

Ελληνικά  Українська

Українська  فارسی

فارسی  Burmese

Burmese  Latine

Latine  Қазақ

Қазақ  Azərbaycan

Azərbaycan  Lietuvos

Lietuvos  Српски

Српски