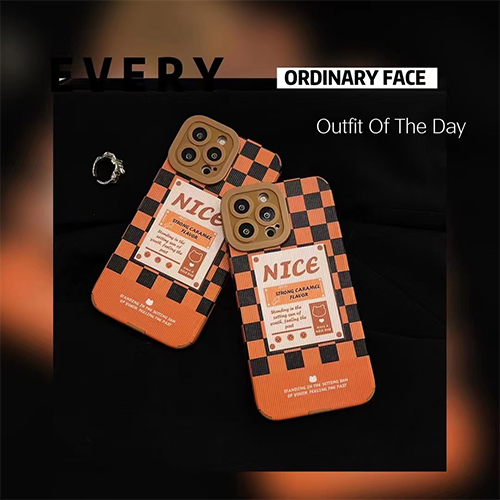

Mobile phone protective cases can be divided into: plastic, TPU, silicone, leather case, crystal case, water case, mesh case, environmental PC case, metal case and wood case.

Traditional processing technology: the market uses more technology is injection molding class, spraying class, printing class, inkjet class, radium carving class, IML class, paste skin class, leather case class, set drill class, oxidation etching class, laser and so on.

Silicone shell

Silica gel material is a very popular material, soft texture, good skid resistance, and has the characteristics of oil resistance and high temperature resistance. Silica gel itself is environmentally friendly, healthy and tasteless, which can relieve the impact of external parts when accidentally falling, and has good protection function.

PC material shell

PC material is a kind of comprehensive excellent hard case, feels more comfortable, at the same time has a good heat dissipation resistance, light PC material case colorful, can provide comfortable touch and fashion visual enjoyment.

Glass shell

glass mobile phone case, bright color pattern, durable, not fade, fashionable and beautiful appearance. Glass material has a certain abrasion resistance and scratch resistance performance, is a widely praised new material.

Metallic shell

At present, the metal mobile phone case on the market is made of aluminum magnesium alloy. This type of mobile phone case has high resistance to deformation and fracture, so it has ideal protection performance. However, the metal case is heavy and poor in portability, which causes certain interference to the signal.

Crystal shell

The crystal shell, which is favored by women, is made of plexiglass and has a solid and translucent appearance. Not only can it effectively protect the phone, but it also does not affect the appearance, it can be described as the long silicone sleeve and leather case.

Buy advice: silica gel material soft texture non-slip, glass material wear-resistant anti-scratch, both of these two materials in appearance or protection performance, certain advantages worth choosing.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  עִברִית

עִברִית  Galego

Galego  Беларус

Беларус  Hrvatski

Hrvatski  Shqiptar

Shqiptar  Bosanski

Bosanski  Frysk

Frysk  IsiXhosa

IsiXhosa  Somali

Somali  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  հայերեն

հայերեն  Lëtzebuergesch

Lëtzebuergesch  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা

বাংলা  Dansk

Dansk  Pilipino

Pilipino  Türk

Türk  Gaeilge

Gaeilge  عربى

عربى  Indonesia

Indonesia  norsk

norsk  Ελληνικά

Ελληνικά  Українська

Українська  فارسی

فارسی  Burmese

Burmese  Latine

Latine  Қазақ

Қазақ  Azərbaycan

Azərbaycan  Lietuvos

Lietuvos  Српски

Српски